The B18 set includes:

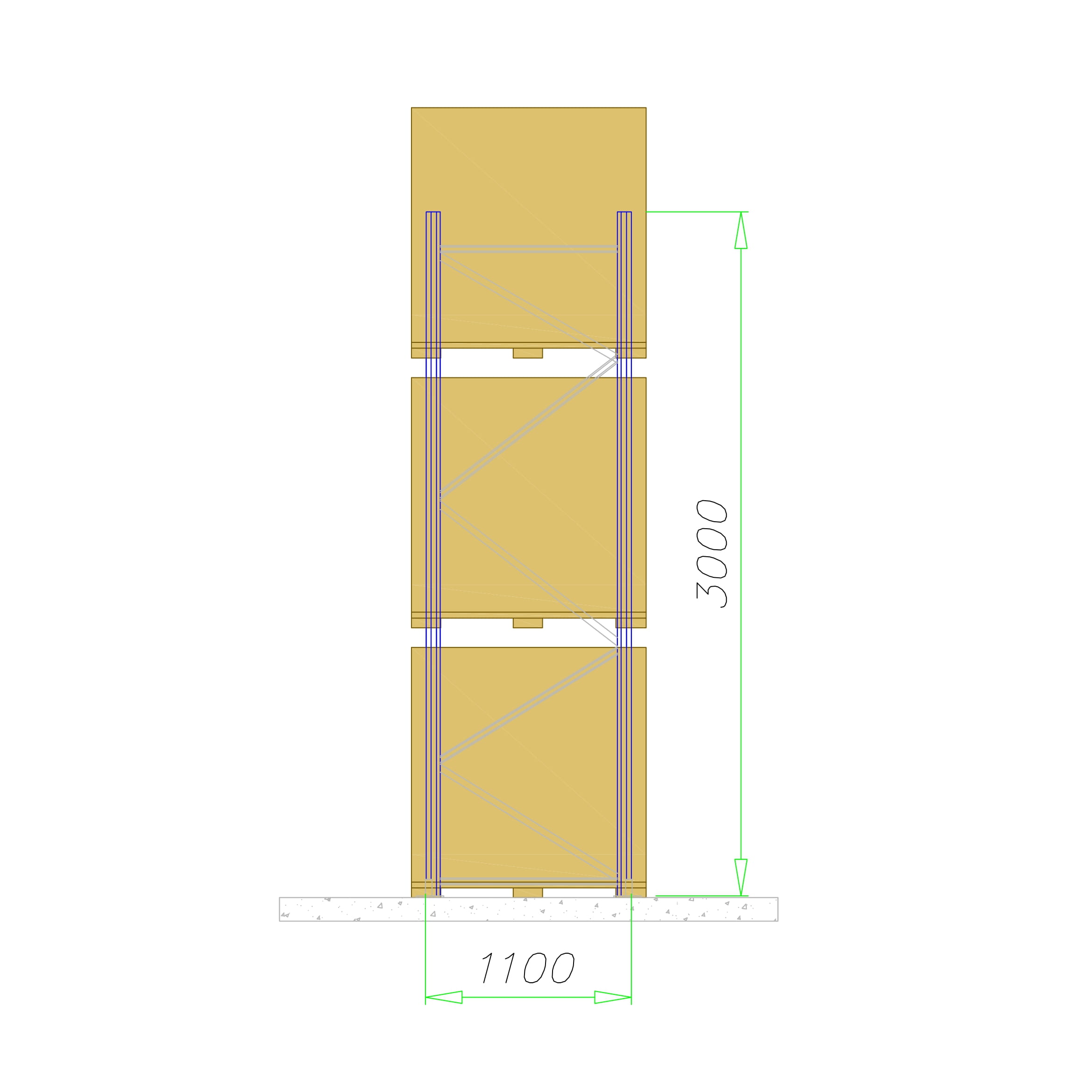

- 4 complete frames, height 3000 mm x depth. 1100mm

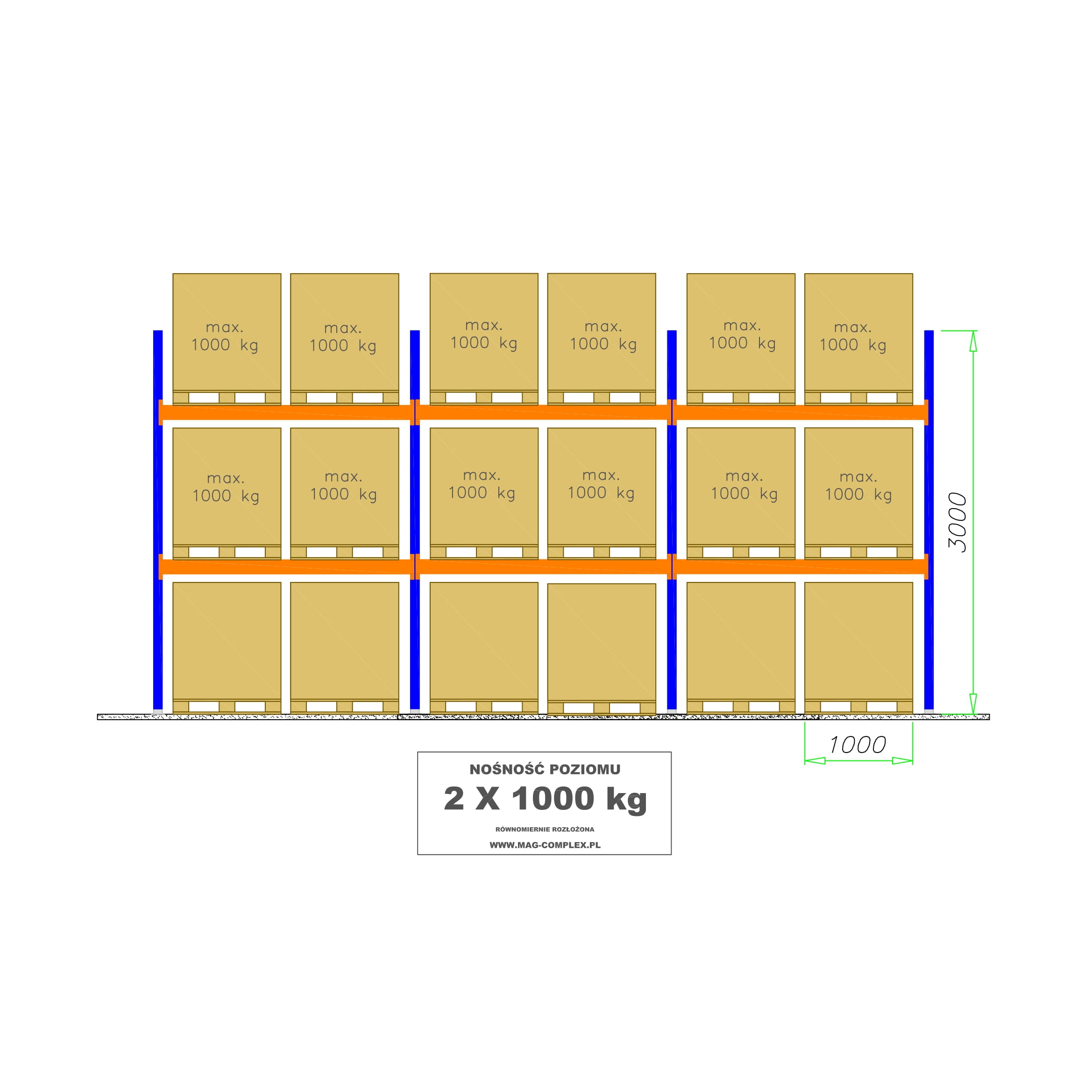

- 12 beams (traverses) 2300 mm, load capacity 2000 kg

- 8 120 mm galvanized anchors

- 4 1 mm galvanized leveling washers

- 2 3 mm galvanized leveling washers

- Load capacity stickers

- Beam protection

- CE Declaration of Conformity

- Pallet rack assembly instructions

- Painting: high-quality epoxy coating

- Level adjustment with 50 mm increment

- Warranty: 5 years

We issue the Declaration of Conformity necessary for the storage of goods, required by the National Labor Inspectorate.

Here is one of the most popular products in our offer. Pallet racks are the most frequently used system for storing palletized goods, and it's no wonder. The Pal Rack® system was created by a team of experienced engineers using modern design software and static calculations. Combined with many years of experience in the construction of warehouse equipment and the support of our customers, this has resulted in the development of top-class pallet racks.

The most important features of the system are high load capacity, modular design and high resistance to damage. Most work on pallet racks is carried out using forklifts, so the Pal Rack® can be equipped with dedicated safeguards that will significantly extend the life of the structure. In addition wide range of accessories allows you to adapt the shelves to the specific requirements of each warehouse and improve work efficiency and increase safety.

Universal pallet rack

The presented configuration will easily accommodate 18 full pallets. Each pair of beams can bear a load of up to 2,000 kg, so the total load capacity of the shelf is as much as 18,000 kg! This durable pallet rack is universal equipment that will work in any warehouse. If you have any questions or would like to learn about the possibilities of rack configuration, write to us or call us! We will be happy to answer all your questions!

A system for storing light and heavy pallets. Its characteristic features are: reliable and stable construction (safety factor 1.4) high quality and a large variety of accessories. This allows for optimal warehouse planning in accordance with the individual needs of the user.

Supporting frame – is composed of 2 columns, several bracings (diagonals) and footings, ensuring excellent buckling and flexural-torsion stiffness. The frames are assembled with screws, which ensures low repair costs in the event of damage by forklifts. Each connection is secured with a self-locking nut. The variety of frames allows you to optimize the structure and achieve a height of up to 30 m and a load capacity of spans up to 45 tons.

Pole – cold bent, crush-strengthened, 12 folds giving exceptional stiffness, width 85 mm, sheet thickness from 1.75 mm to 2 mm.

Sbracing (diagonal) – connected using screws with a semi-closed profile, made of galvanized sheet metal.

Feet – galvanized, hot-dip galvanized, each time converted into loads transferred from the column to the floor for even distribution of loads. Each foot is attached to the floor with a very durable M12x100 anchor.

Bar – composed of closed profiles and connectors with special hooks.

Perforation – special perforation that can only be made on CNC machines with very small manufacturing tolerances, giving an extraordinary structure stiffness.

Quality indicators for shelves: ISO 14001, ISO 9001, ISO 9002 certificate.

Strength calculations for shelves:

All static calculations of the structure as well as the arrangement and dimensions of the shelves were made in accordance with the FEM 10.3.01 and FEM 10.2.03 standards.

*The operating and assembly manual is available for download in the "my account" tab after purchasing the product