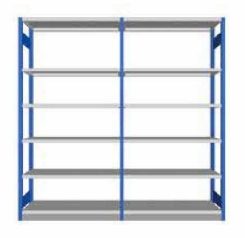

Mshelf ® shelves can be used in any environment, from an office to an industrial warehouse. The designed shelf system is intended for light and medium loads up to 200 kg/shelf. Thanks to the frame that can carry a load of up to 4000 kg, it is possible to create a multi-story rack structure.

Construction of the mShelf shelf rack

1. Pole

2. Closed frame

3. End frame

4. Shelf

5. Rear bracing

6. Back net

7. Half-height divider

8. Etiquette

Benefits of using mShelf shelf racks

- Compliance with European FEM and EN standards and ISO 9001 certification

- All components have been thoroughly tested in specialized laboratories

- Design and static calculations using specialized software

- Fully automated production process, guaranteeing high quality and reducing costs

mShelf shelves - Frame and vertical pole

The frame consists of two Mshelf vertical columns and a frame bracing system. Side rectangular holes allow the installation of shelf clips every 25mm. Round holes are used for screwing or riveting various types of bracing.

Shelves - unique design

- The shelf length corresponds to many types of cartons and plastic containers

- The closed profile edge will not twist under heavy loads

- Front profile ideal for attaching labels

- The shorter side of the shelf is triple bent

- Double-folded corners that are joined together provide high stiffness and resistance to heavy loads

- The edges are not sharp, which prevents cuts

- The shelves are perforated every 53mm, which allows for the installation of vertical partitions

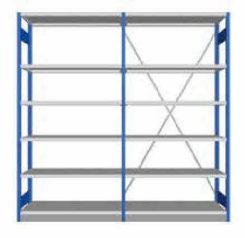

Framework - mShelf

- open

- closed

- concentrated

Standard open frame with horizontal braces. It can be used in single-story installations up to a height of 4.5 m with a maximum span load of 2000 kg.

Closed frame with intermediate panels. For low- and high-span installations. For span loads up to 4000 kg.

Open frame with diagonal. For use in multi-story installations and for storing heavy loads. Span load up to 4000kg.