PALLET RACKS - Offer

click here and check the offer for pallet racks in the online store

Pallet racks are one of our most popular products. And it's no wonder - transporting goods on pallets is the basis of European industry, so warehouses must also be adapted to it. This has many advantages - primarily far-reaching standardization. Unfortunately, the pallets themselves are not always made precisely, so the shelves for storing them must be prepared for their defects and damage, and at the same time enable quick loading and unloading. Additionally, they must be resistant to impacts from forklifts in a busy warehouse and withstand enormous loads.

For these reasons, when designing our system Pal Rack®, we used the latest technologies. A team of experienced engineers, specialized software and many hours spent on static calculations. All this to be absolutely sure that the solutions created will be optimal. All components then underwent exhaustive laboratory testing and certification. In this way, we have created top-class pallet racks that allow you to use the potential of the warehouse and enable effective work.

Construction of pallet racks

Our pallet racks meet the strict requirements of FEM (Fédération Européenne de la Manutention). However, the most important thing for us was to obtain an easy-to-use system that can withstand heavy loads and is also resistant to damage. In the event of destruction of individual elements by a forklift the repair is quick and inexpensive. This is due to the modular design. It also allows you to easily modify the shelves and adapt them to changing needs. But how are pallet racks in the Pal Rack® system actually constructed?

Pallet racks – frames

The frames consist of two columns and bracing. The number of bracing depends on the height of the shelf and the expected loads. Frame elements are connected with screws, which reduces costs in the event of damage and facilitates repair. Each of these connections is secured with a self-locking nut. The variety of frames allows you to optimize your design and achievement height up to 30 m and span load capacity up to 45 tons.

Pallet racks – end hook

Unlike frame elements, the beams are mounted without screws. This is made possible by a special connector made of high-strength carbon steel. Simply insert the beam from the top and secure it with a special clip to prevent it from accidentally sliding out. Thanks to this, installation is extremely quick, and changing the height at which the beam is mounted takes place in a few moments. This allows for easy, self-adjustment shelf to suit your current needs.

Pallet rack beams

To ensure a wide range of possible structures, we offer: four types of beams carriers. Each of them has different properties, but what they have in common is precision of workmanship and high durability. Like the frames, the beams are powder coated, which protects them against corrosion, abrasions and impacts. Additionally, they are available in many sizes.

- Cold formed closed profile beam. The closed section section of the beam is reinforced at the top and bottom to prevent local damage when loading heavy pallets. Available in width from 60 to 125 mm.

- Beam composed of two C profiles. The beam is composed of two cold-formed C-shaped profiles, together forming a closed profile. It is very resistant to torsion and provides high stiffness in the vertical and horizontal directions. Its load capacity is up to 4.8 tons per beam level. It is available in widths from 110 to 160 mm.

- Beams for shelf levels (picking). Light beam with integrated connector. This beam is equipped with a standard 28 mm thick shelf edge and panels. Perfect for storing light loads.

- Beam for heavy loads. A beam composed of two C profiles with an L profile welded below the edge, supporting the chipboard. The shelves are flush with the top edge of the beam. This is the choice for really heavy tasks.

Delivery and acceptance level

P&D, i.e. delivery and reception levels, are simply places for storing pallets, mounted on the extreme elements of the rack frame. By installing them, you will increase the capacity of the shelf while maintaining the width of the working corridor unchanged. They can be equipped with a centering element, thanks to which pallets can be stacked quickly and precisely.

Methods of strengthening pallet racks

Our pallet racks can reach up to 30 meters in height, but even more typical structures require stiffening. The basic method of strengthening is the installation of bracing. In the case of narrow single racks, a gable connection with an adjacent double rack is used.

Pallet racks – bracing

The bracing of the rack structure is intended to increase the loading capacity of the racks. In some installations, they are necessary to ensure the stability of the structure. The vertical bracing (also called rear bracing) is located at the back of the rack. It works in a vertical plane. Horizontal braces are installed between two beams, which gives the whole structure stability in the horizontal plane. Thanks to this relatively simple solution, the load-bearing capacity and durability of pallet racks significantly increases.

It sometimes happens that a single shelf is too narrow to be sufficiently stiffened with braces. In such cases, it is connected to the nearest double shelf using a gable attachment. The mounting is placed on the extended front pillars of the frame. In the case of automatic racking, the gable mount is also used to support the top rail that guides the automatic stacker crane.

Pallet racks with narrow aisles

This is an option for those who want to improve their work and introduce system solutions. It requires use VPN carts. These trolleys will be guided along a narrow working corridor, making the operator's work much easier and reducing the risk of accidents. For this purpose, inductive guidance is increasingly used instead of the traditional rail one.

We design the shelves and the guidance system taking into account a specific trolley, adapting them to its dimensions and capabilities. Please note that guide rails with a low profile allow the pallet to be placed directly on the floor, while those with higher profiles require the installation of an additional "zero" beam level at the bottom. Pallet racks with narrow aisles are a great solution that allows you to maintain perfect order and increase work efficiency!

contact us regarding the valuation of pallet racks

- by phone number +48 58 535 16 96

- by sending an e-mail sekretariat@mag-complex.pl

- using contact form

QUESTIONS & ANSWERS

more about pallet racks

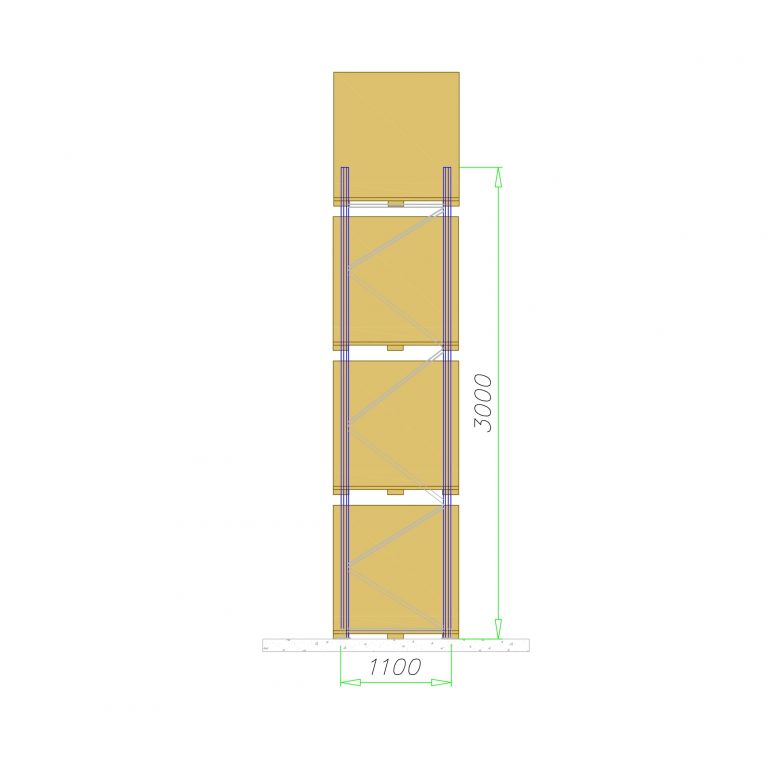

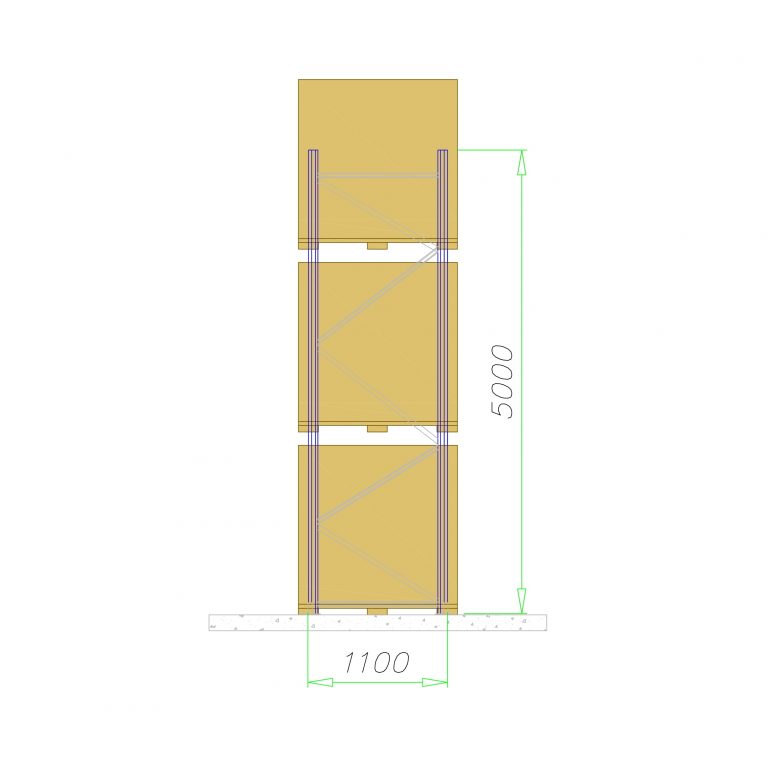

The shelf consists of frames and beams.

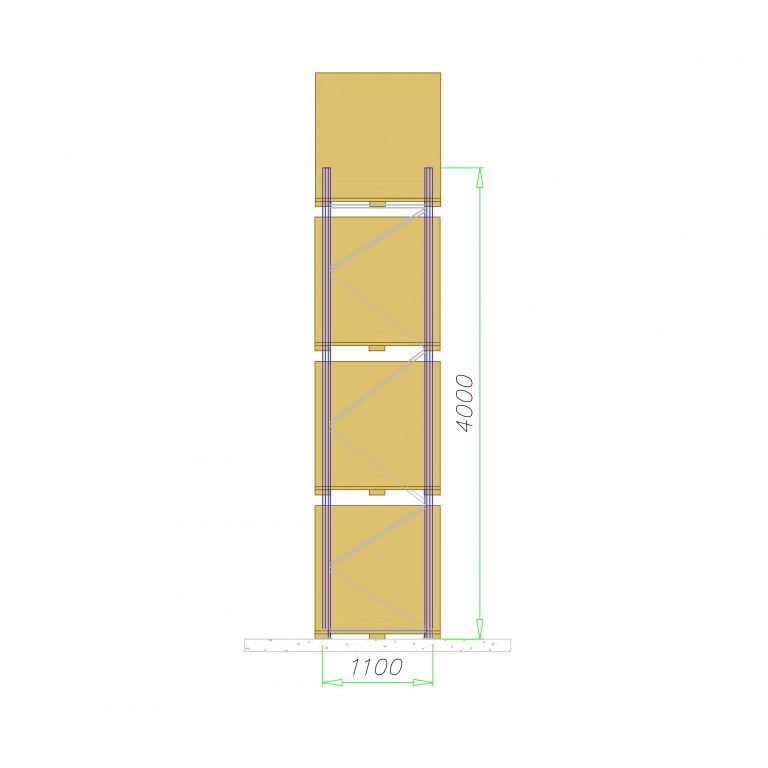

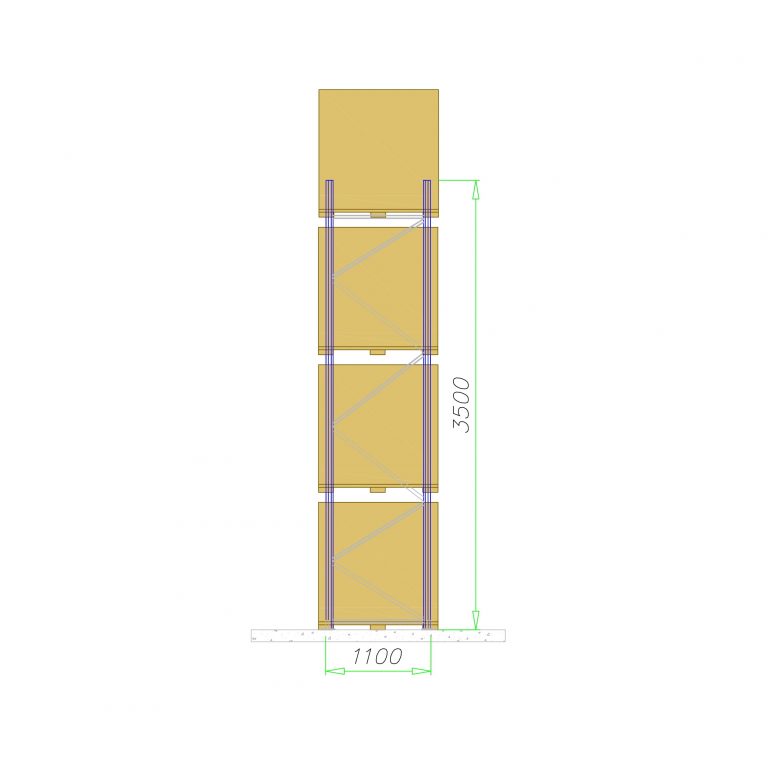

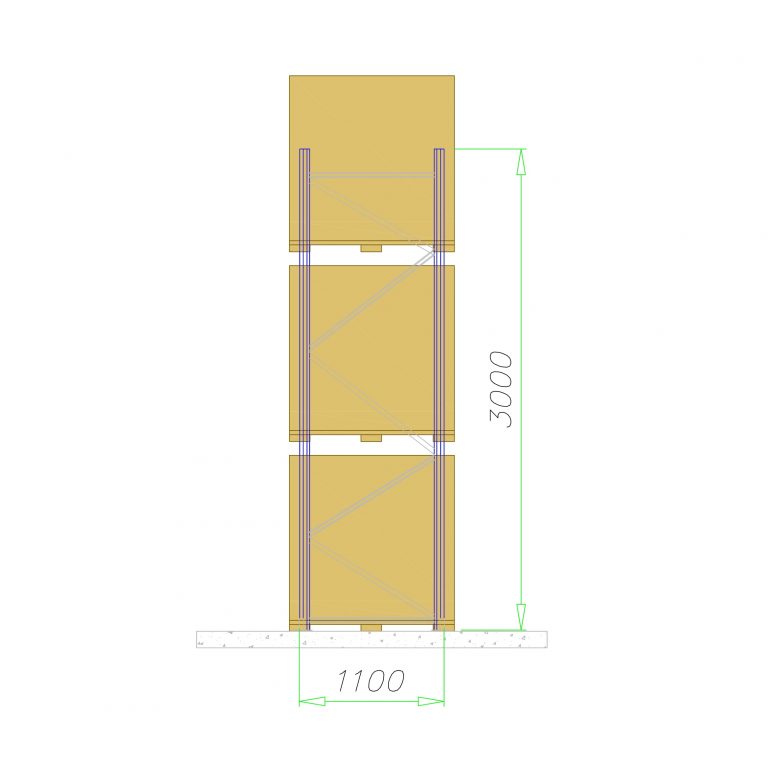

The frame consists of two poles connected by diagonal braces which, after screwing, are anchored to the ground. The system is complemented by beams (standard: 2) and constitutes a beam level.

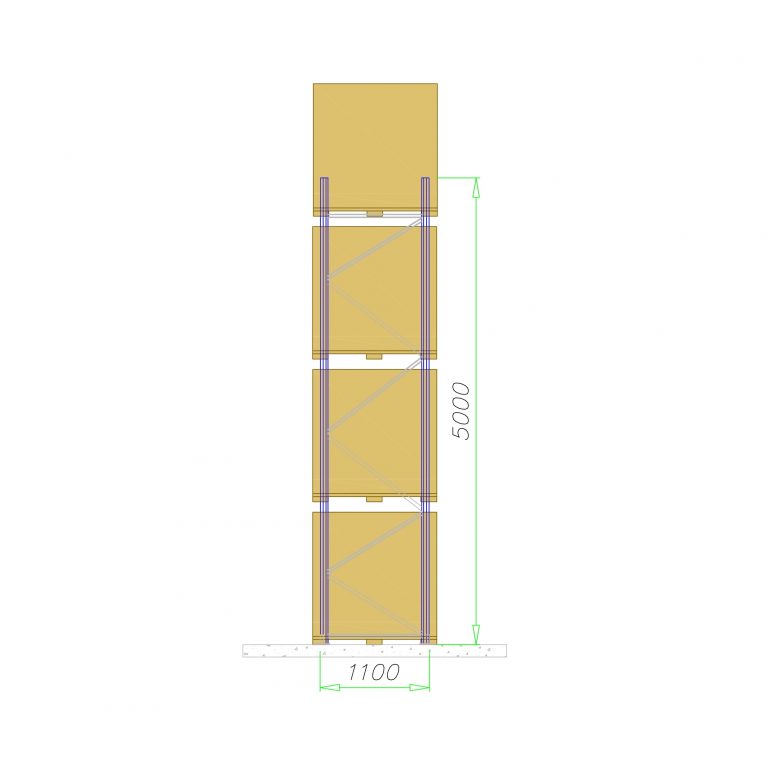

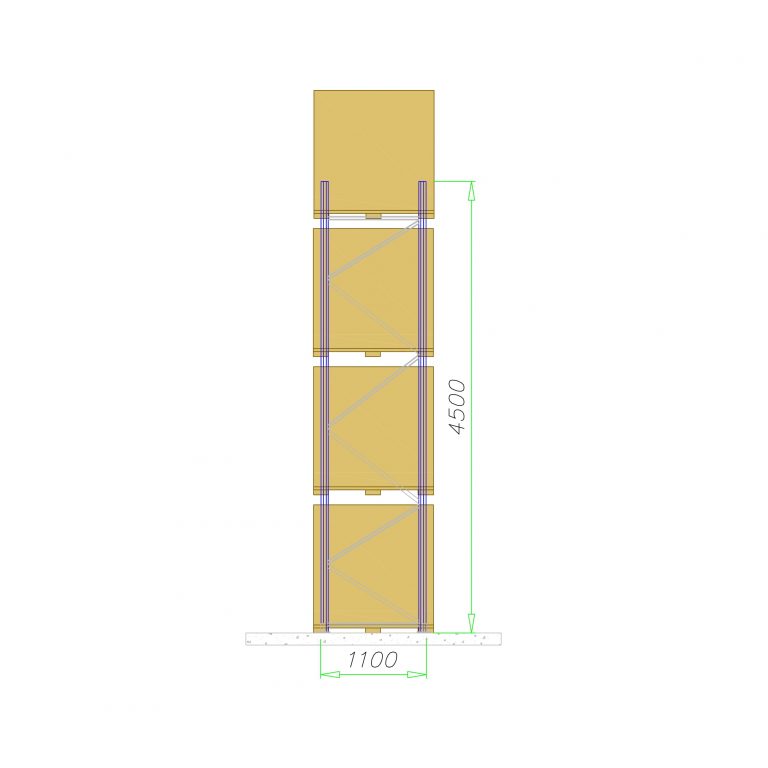

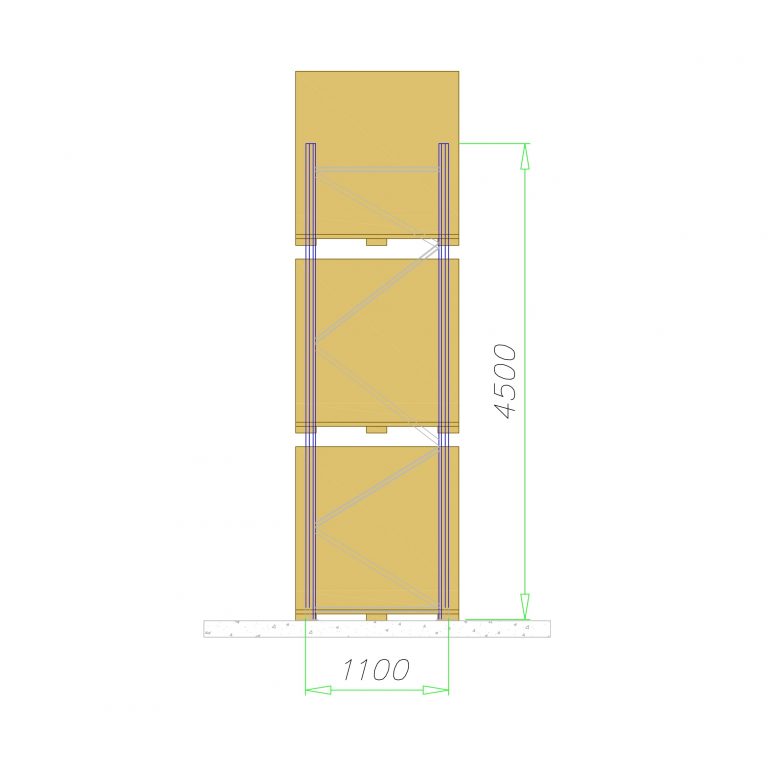

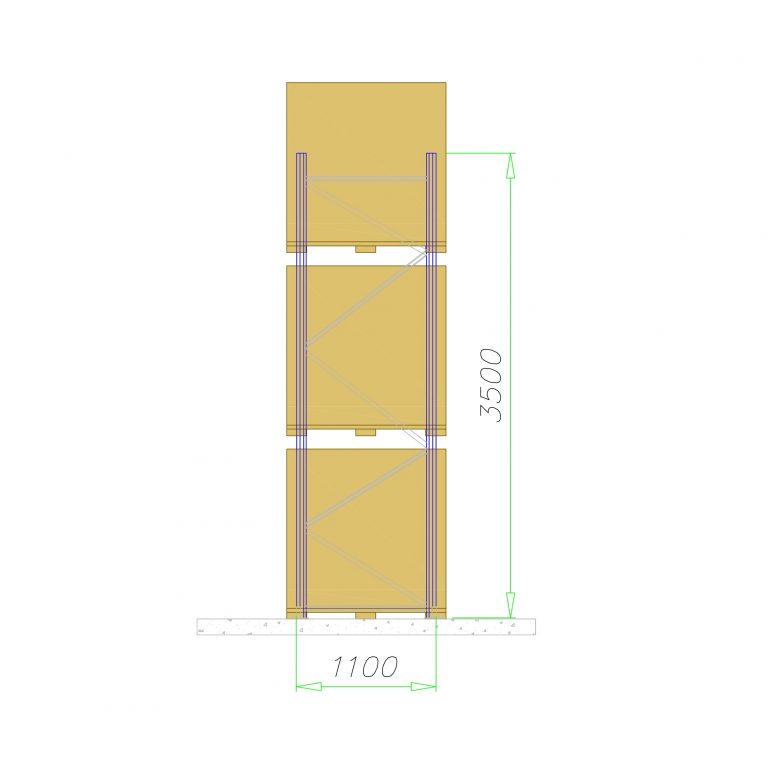

The standard rack depth of 1,100 mm allows for the storage of pallets with a depth of 1,200 mm, but the rack depth can be adjusted to other pallet dimensions, e.g. for storing chipboard with dimensions of 2800x2070mm, we use shelves with a depth of 1900mm, where the frame consists of 3 columns and the beam level consists of 3 beams.

Yes, the frame poles are perforated every 50mm, which allows the beams to be fastened lower or higher. Please remember to maintain the appropriate working height between the beam levels for the work of the trolley when stacking and removing pallets with goods.

We can also store other forms of storage apart from pallets on shelves, but the shelves must be adjusted accordingly.

We have a number of accessories that allow you to adapt the shelf to smaller packages, e.g. mesh shelf, crossbars recessed under the chipboard, crossbars placed on beams, wema grid.

For installation, a floor with a minimum height of 150 mm, made of concrete of at least B25, is required. The substrate should be adapted to transfer the loads from the shelf system with goods.

No, paving stones do not meet the requirements of the substrate for pallet racks.

The basis in every warehouse is the height of the hall and the lifting height at which we have or will have the trolley with which we will operate the system.

The frames do not have to be installed right up to the roof, but lower by the height of the package at the highest beam level, because the last level can be mounted on the last perforation of the column.

You should consider how you will arrange the pallets on the levels, whether they will all be of the same height and the same weight. As a rule, we place the heaviest packages at floor level, and the higher, the lighter and lower. Thanks to this vision, beams with the appropriate load can be adjusted to a given level.

The pallet rack is characterized by the widest and highest frame in storage systems available on the market. Thanks to a wide range of lengths and load-bearing capacities of beams and columns, we can adapt the shelves to any warehouse or hall.

Unfortunately, there are situations when the trolley operator hits the rack pole during loading, which is why steel and plastic bumpers are available in our store.

The steel fender is mounted at the front leg of the frame and anchored to the ground to protect the lower part of the pole, where damage most often occurs.

A polyethylene cover mounted on any section of the pole is also available,

resistant to impacts and abrasions, and thanks to its structure, easy to assemble and dismantle.

PALLET RACKS

storing goods on pallets

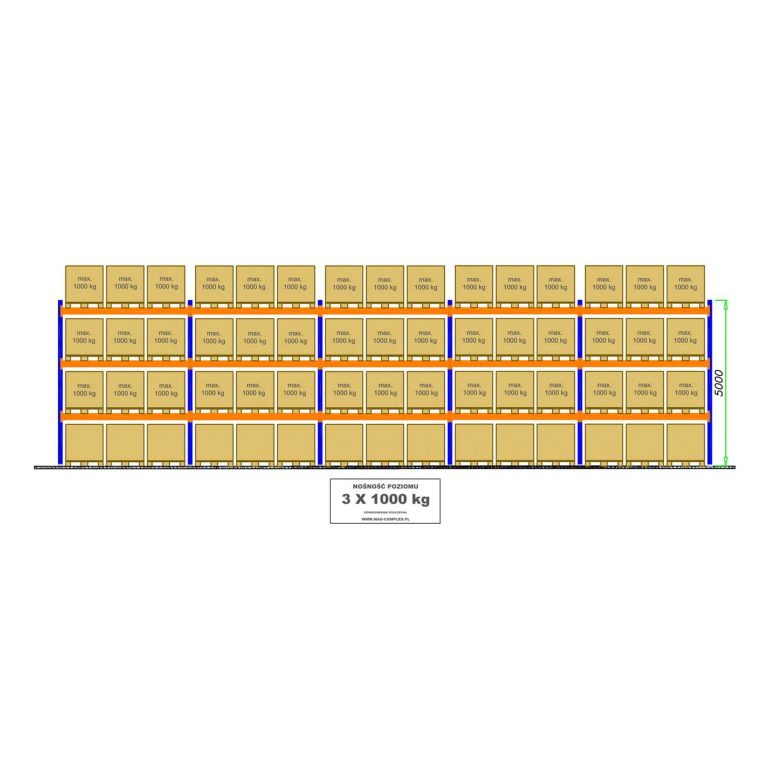

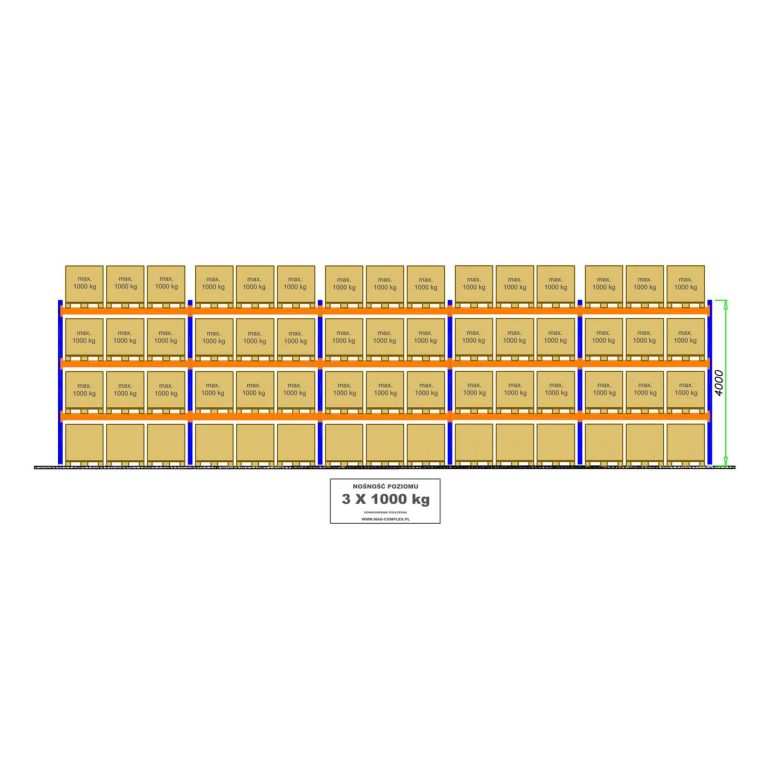

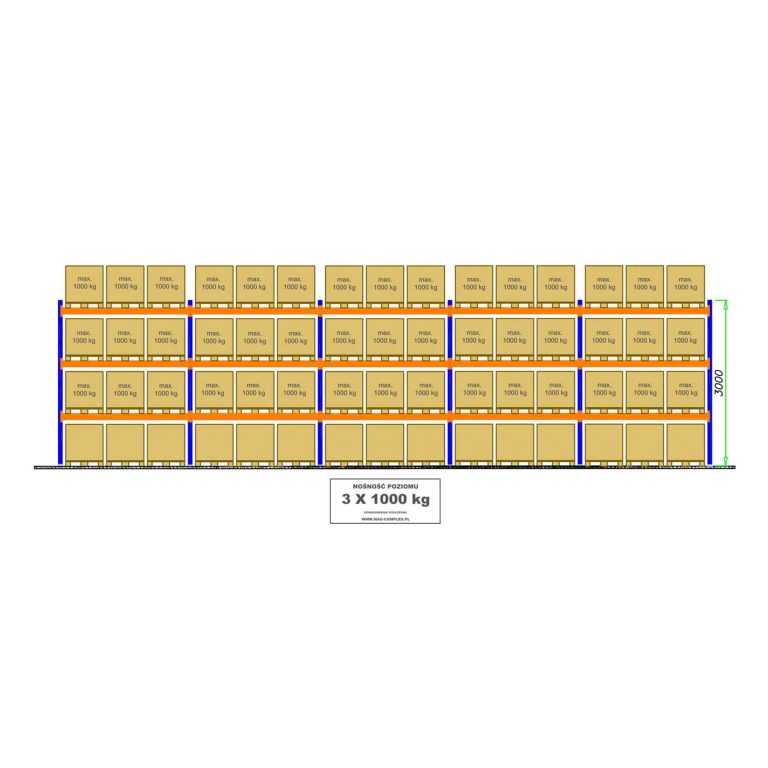

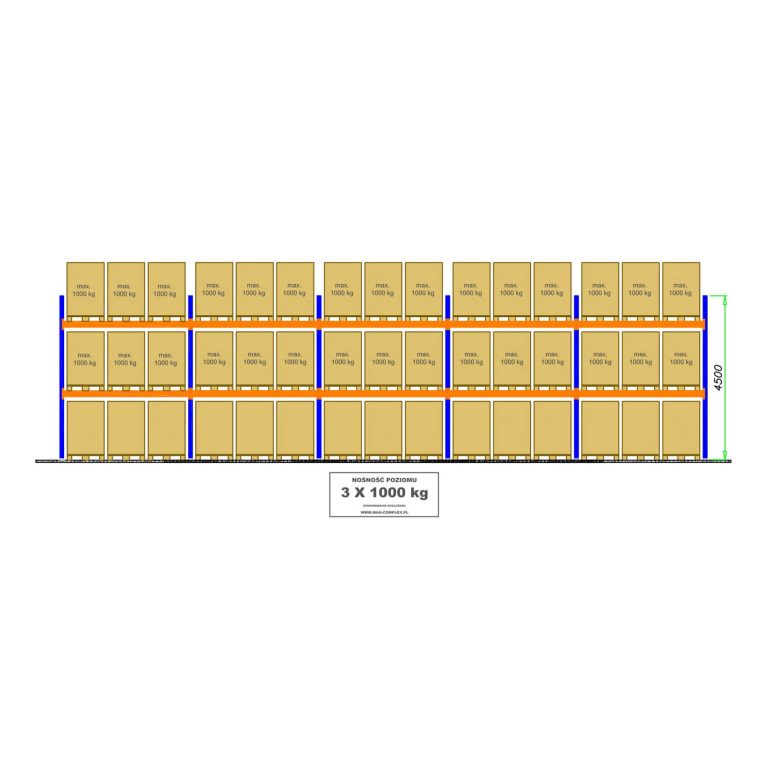

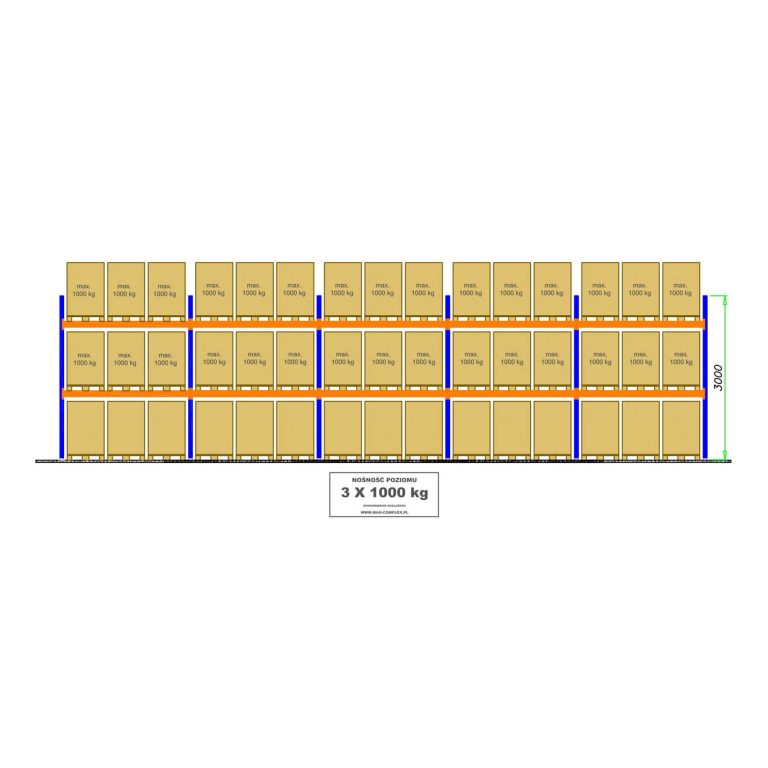

B155 pallet rack L=14010mm 60 pallets – 1000kg 0+3

8 830,00 zł net10 860,90 zł gross

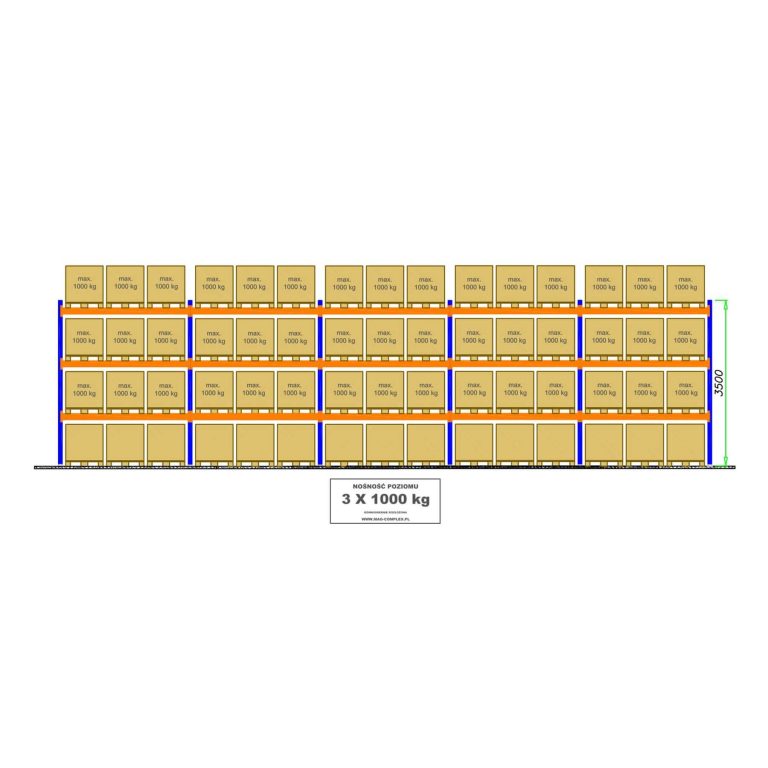

B155 pallet rack L=14010mm 60 pallets – 1000kg 0+3

7 720,00 zł net9 495,60 zł gross

B155 pallet rack L=14010mm 60 pallets – 1000kg 0+3

7 080,00 zł net8 708,40 zł gross

B155 pallet rack L=14010mm 60 pallets – 1000kg 0+3

6 770,00 zł net8 327,10 zł gross

B155 pallet rack L=14010mm 60 pallets – 1000kg 0+3

6 460,00 zł net7 945,80 zł gross

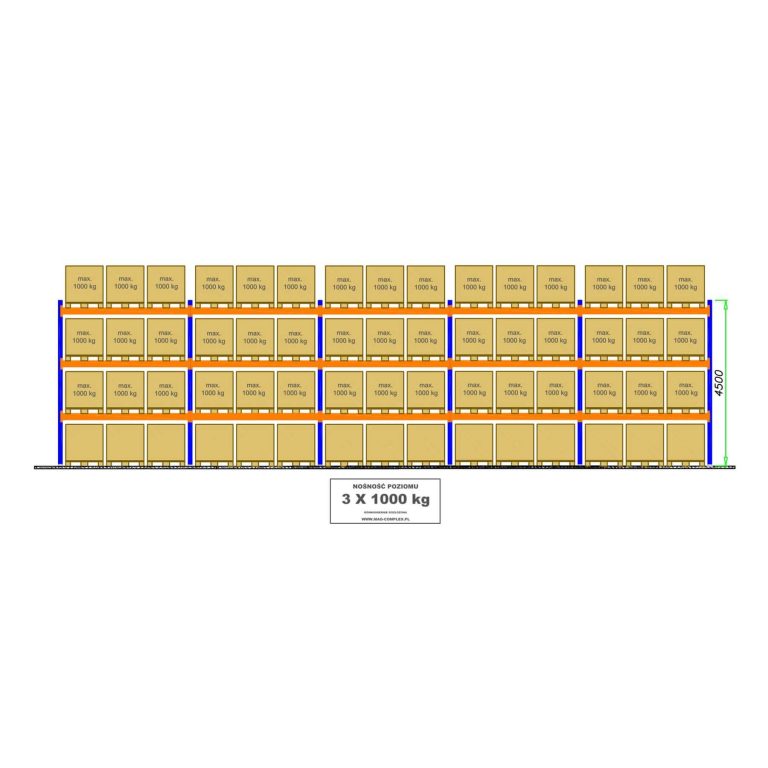

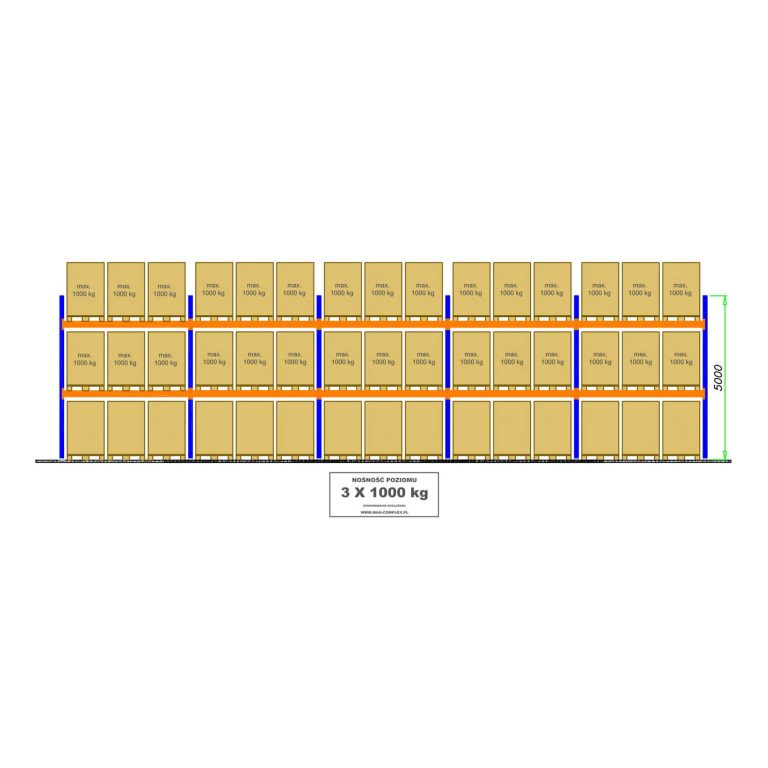

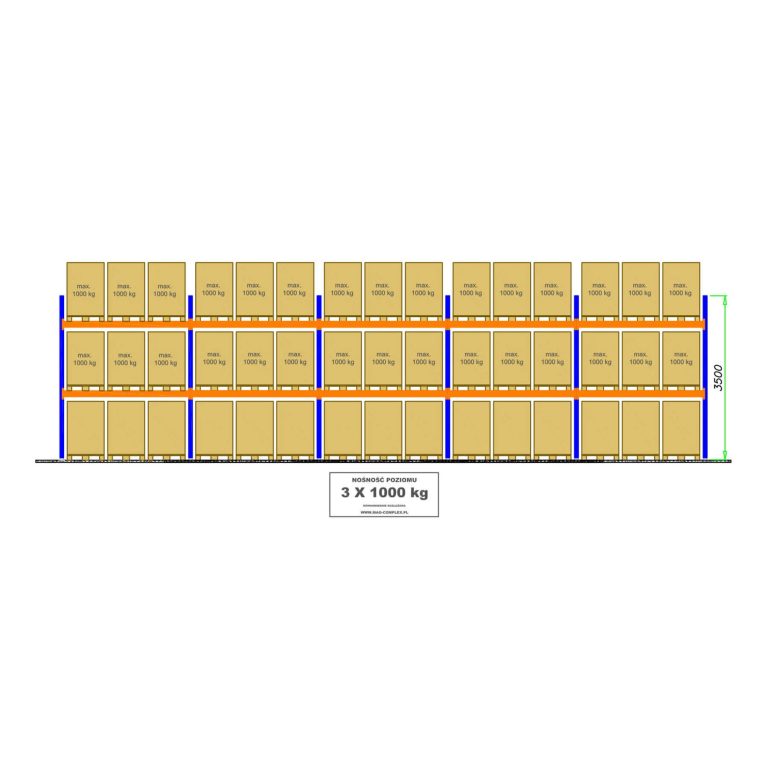

B149 pallet rack L=14010mm 45 pallets – 1000kg 0+2

7 370,00 zł net9 065,10 zł gross

B148 pallet rack L=14010mm 45 pallets – 1000kg 0+2

6 260,00 zł net7 699,80 zł gross

B147 pallet rack L=14010mm 45 pallets – 1000kg 0+2

5 310,00 zł net6 531,30 zł gross

B146 pallet rack L=14010mm 45 pallets – 1000kg 0+2

5 000,00 zł net6 150,00 zł gross